What are food safety risks?

June 26, 2025What is a Quality Management System? (QMS)

June 30, 2025Food allergies affect millions of people worldwide and can cause severe, sometimes life-threatening reactions. In the food industry, allergen control is not just a legal obligation—it is a critical component of consumer safety and trust. Implementing effective allergen management programs through systems like HACCP (Hazard Analysis and Critical Control Points) and Good Manufacturing Practices (GMP) helps minimize risks and prevent cross-contamination. Today, the Food Safety Alliance will discuss the importance of allergen control, highlight common food allergens, share potential risks, and provide tips on how to ensure food is produced in a safe environment.

Why is allergen control important?

Allergens are substances—usually proteins—that trigger inappropriate immune responses in sensitive individuals. Even small amounts can cause reactions ranging from mild skin irritation to anaphylactic shock. Since there is no cure for food allergies, the best approach is strict avoidance of allergens for those affected.

Food businesses are legally responsible for controlling allergens, properly labeling products, and preventing cross-contamination. Failure to meet these obligations can lead to consumer harm, product recalls, legal penalties, and damage to brand reputation.

Allergens

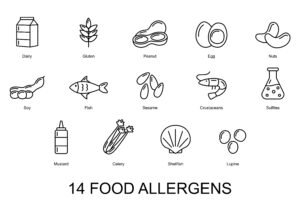

Globally, most countries recognize a group of major allergens. These allergens must be declared on food labels, according to Georgia’s Decree No. 301:

Cereals containing gluten (e.g., wheat, rye, barley, oats)

Crustaceans (e.g., shrimp, crab)

Eggs

Peanuts

Soy

Milk (including lactose)

Tree nuts (e.g., almonds, hazelnuts, walnuts, etc.)

Celery

Mustard

Sesame seeds

Sulfur dioxide and sulfites (in concentrations over 10 mg/kg or 10 mg/L)

HACCP and Allergen Control

The HACCP system is a preventive approach to food safety that helps identify and manage risks at every stage of food production. In terms of allergens, HACCP supports:

Identifying allergenic ingredients used in recipes.

Assessing the risk of cross-contamination during storage, processing, production, and packaging.

Allocating dedicated production lines, hygienic tools, and maintenance equipment for allergen-containing products.

Implement verification and validation procedures, such as cleaning validation and allergen testing, to minimize the risk of allergen contamination in food.

In HACCP terminology, allergens can be considered hazards, and in some cases, allergen cross-contamination may be designated as a Critical Control Point (CCP).

Risks of Improper Allergen Management

Improper allergen management can lead to serious consequences:

Unintentional cross-contamination: Occurs when allergens are transferred from one product to another through tools, equipment, or other points of contact.

Incorrect labeling: Misleads consumers and results in legal violations.

Incompetent staff: Lack of training can lead to improper handling or breaches in sanitation procedures.

To prevent these risks, businesses must integrate allergen control across all operations—from procurement through every stage of production to final packaging.

Prevention Strategies

Allergen prevention is a complex effort that combines planning, discipline, and monitoring. Here are some essential steps:

Identifying allergens

Receiving, controlling, and labeling allergen-containing ingredients

Storing allergens in clearly separated areas within the warehouse

Maintaining proper production sequencing for allergen-containing products

Communicating clearly with consumers

Conclusion

Allergen control is one of the key aspects of modern food safety and consumer protection. Through a combination of HACCP, GMP, staff training, and preventive measures, food businesses can significantly reduce the risk of allergen contamination and protect their customers. Every step matters—from receiving ingredients to delivering the final product to the consumer.

Food safety is not just about prevention—it’s about earning trust.

Check out our blog on cross-contamination or register to attend our training sessions on July 1 and 2.

ჯვარედინი დაბინძურება – მარტივი წესები, რომლებიც უნდა იცოდეთ