5 Mistakes During HACCP System Implementation

January 21, 2026

How to implement HACCP?

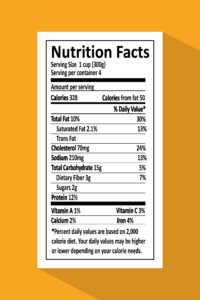

February 14, 2026Imagine a shopper in your store pointing their phone at a salad package and instantly seeing verified nutrition facts, allergen flags, farm-of-origin photos, and a certified cold-chain timeline — all pulled live from the product’s digital identity. This is not sci-fi. Combining item-level RFID (and NFC) with verified nutrition and sourcing data is turning packages into interactive health tools — and it’s a major commercial opportunity for brands, retailers, logistics providers, and label suppliers.

Why RFID + Verified Nutrition matters now

Consumers are more health conscious than ever. They want transparency (not marketing-speak), quick ways to check whether a product fits their diet, and reassurance that the label they read is accurate and up to date. Smart packaging — RFID or NFC chips paired with a secure backend that holds verified nutrition and sourcing records — gives consumers a simple scan = verified-truth experience.

For businesses, that translates into real value:

stronger brand trust and differentiation,

fewer returns and fewer allergic reactions or misinformed purchases,

smoother recalls and regulatory audits because every item has a verifiable history,

new marketing and loyalty touchpoints (personalized offers, recipes, subscription refills).

What happens when consumers can scan a product and see verified nutrition + sourcing data in real time?

Short answer: the purchase becomes interactive, personalized, and safer.

Longer answer — the shopping experience shifts in four ways:

Instant trust. A scan that shows lab-verified nutrition values and an unbroken sourcing ledger reduces skepticism and delivers confidence at the moment of purchase.

Personalization at the shelf. Apps can compare scanned nutrition to a shopper’s saved preferences (keto, low-sodium, allergies) and highlight what fits, suggest swaps, or show portion guidance.

Faster, smarter recalls. If a batch has an issue, RFID lets brands identify exactly which items shipped where — minimizing cost and customer inconvenience.

Proven sustainability claims. Consumers can see certifications, farm photos, and recycling instructions linked to the exact item they’re buying — not a vague brand-level claim.

These outcomes aren’t hypothetical; they’re emerging in pilot projects and commercial rollouts where RFID/NFC is paired with secure traceability systems and verified data stores. Academic and industry trials show RFID systems significantly improve traceability and operational visibility across packaging lines.

Standards and regulatory reality: what businesses must know

Smart packaging isn’t just a technical choice — it has standards and compliance requirements. Global standards bodies and industry guidelines help make RFID practical and interoperable while protecting consumers:

GS1 guidance is the backbone for item identities and RFID use in commerce; follow GS1’s EPC/RFID guidelines to ensure your tags and data models will be usable across retailers and systems. Compliance with these standards is crucial for large retailers and foodservice customers. GS1

Industry-specific tagging rules (for example, foodservice case/carton tagging) are already in circulation; companies must align tag encoding and placement with buyer expectations to avoid rework.

Regulatory changes around packaging and sustainability (e.g., new packaging/packaging-waste regulations in some markets) mean smart tags and removable/compatible electronics are increasingly a design consideration for recyclability and material safety.

Meeting these requirements early prevents supply-chain friction. Brands that standardize on GS1 identifiers, plan for tag removability or recycling, and work with traceability providers save time during onboarding to major retailers.

Practical tech choices: NFC vs RFID vs QR

RFID (UHF) is best for fast, item-level reads in warehouses and checkouts — ideal where inventory accuracy and automated flows matter.

NFC (a form of RFID) is perfect for consumer phones: a single tap/scan reads the product’s URL or token and shows the verified record.

QR codes are cheap and useful, but they can be copied and offer weaker authenticity guarantees compared with cryptographically signed data linked to an RFID/NFC identity.

A hybrid approach — UHF RFID for supply-chain operations + NFC for consumer scan points — often gives the best balance of efficiency and user experience.

Who’s already building this? A look at solution providers

Companies that package traceability as a service are stepping into the gap between manufacturers and retailers. For example, Altinteg and similar providers offer end-to-end RFID labels and traceability stacks that emphasize sustainability and consumer-facing interactions — making it easier for brands to launch interactive nutrition/sourcing experiences without building the whole backend themselves. Working with such partners speeds pilot-to-scale deployments.

Business playbook: how to start (and scale)

Pilot a single SKU. Prove the consumer scan → verified view flow with one high-value product line. Measure engagement and conversion.

Adopt GS1 identifiers and tag specs. This avoids downstream retailer compatibility headaches.

Design for recyclability. Consider tag placement and removable modules so packaging stays compliant with waste and recycling rules.

Secure your data. Use cryptographic signatures or blockchain-style audit trails so nutrition/sourcing claims are auditable.

Partner for consumer UX. Don’t just show raw data — translate it into quick “fit for me?” answers, serving busy shoppers.

An invitation to act

Smart packaging that combines RFID with verified nutrition and sourcing data is a competitive advantage for brands that care about trust, health, and sustainability. The technical building blocks exist, standards are mature enough to start, and solution partners are ready to help run pilots. For businesses in food, supplements, and fast-moving consumer goods, the question isn’t if — it’s how fast you’ll give consumers the power to scan, learn, and buy with confidence.

If you want, I can draft a one-page pilot plan for your top SKU (budget, tech stack, KPIs) that aligns with GS1 best practices and recyclable-tag design — or suggest partners to approach for a proof-of-concept.