What risks do Georgian mineral waters contain?

May 15, 2025

What are food safety risks?

June 26, 2025In today’s global food industry, ensuring food safety is not just a regulatory requirement-it is a responsibility that can break consumer confidence and tarnish a company’s reputation. The introduction of smart cold chain monitoring systems in Georgia is starting to gain a foothold, smart monitoring systems help to control the temperature regime of perishable products that travel thousands of kilometers through a variety of climates and storage conditions before reaching the end user’s table. Today, the Food Safety Alliance will tell you what smart cold chain monitoring systems are, what are the advantages and disadvantages of temperature changes in product quality and what impact they can have on food safety.

With the rise of smart sensors, real-time data and digital transformation, cold chain monitoring has evolved into an intelligent system closely related to the principles of HACCP (hazard analysis and critical control points).

What is a cold chain monitoring system?

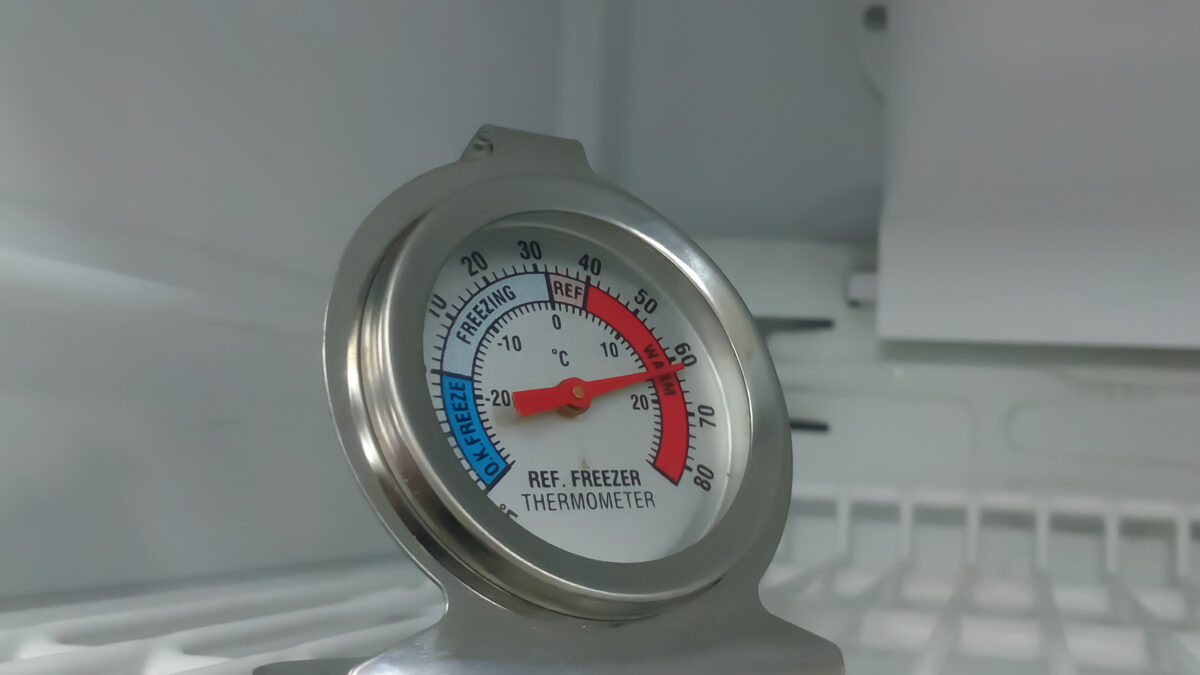

The Cold Chain Monitoring System monitors the temperature of perishable products at all stages of the entire supply chain from production to distribution. Whether dairy products, meat, seafood or vaccines, these products require consistent temperature conditions to prevent spoilage and contamination.

The system includes a combination of hardware and software—thermometers, GPS trackers, smart sensors and cloud-based platforms-to collect and analyze temperature and humidity management conditions in real time. This continuous monitoring ensures the timely adoption of corrective measures before a small deviation becomes a serious risk.

Smart sensors

Manual temperature record production in the journal is slowly becoming a thing of the past, as during such control it is possible that the response to the temperature change is delayed. Smart sensors provide accurate, real – time data collection and alert users when temperatures go beyond set limits. These wireless, battery-powered devices can be placed in trucks, cold rooms, and refrigerators 24/7 to monitor environmental conditions.

The advantages of smart sensors in cold chain monitoring include:

- Real-time notifications via SMS or app notifications

- Cloud storage for data traceability and compliance

- Remote access to temperature data for instant decision

- Reducing food waste through early detection of cold chain disorder

An unmonitored or poorly managed cold chain poses critical food safety hazards. Common risks include:

- Microbial growth: most pathogens such as salmonella or Listeria monocytogenes thrive in the “dangerous zone” (5°c–60°c). If products are exposed to this range over a long period of time, the risk of foodborne illness increases significantly.

- Cross contamination: improper handling or condensate from variable temperatures can cause contamination.

Spoilage: even if microbial risks are avoided, poor temperature control reduces food quality, affecting taste, texture and nutritional value. - Economic losses: spoiled inventory, product recall, and brand reputation damage can lead to serious financial losses.

When these risks go unnoticed, the integrity of the entire supply chain collapses—and consumer safety is neglected.

How cold chain monitoring supports HACCP

The strong cold chain monitoring system directly supports HACCP, which is a globally recognized food safety management system focused on identifying and controlling hazards.

- Hazard analysis

- Critical control points CCPs:

- Critical limits

- Monitoring procedures

- Corrective actions

- Verification

- Documented information

Conclusion

Smart cold chain monitoring systems are more than just a technical trend—they are the mainstay of modern food safety. Ebuilding company can provide this service in Georgia. By using smart sensors and digital tools, businesses can significantly reduce food safety risks, comply with HACCP principles, and establish a stronger connection with customers.